Home » Products » Mobile Communications » Connecting Components » Cluster Connector

The SPINNER Cluster Connector

Beyond Multi-Coax: The SPINNER Cluster Connector Evolves with Your Requirements

AI, self-driving vehicles, the Internet of Things, and virtual reality are rapidly advancing. Naturally, this places increasing demands on mobile communication networks. A wide range of transmission and connection technologies is already in use, with more continuously emerging to meet new demands. As a result, mobile communication infrastructure—especially base stations and antennas—must handle a complex variety of interfaces: coaxial, DC, AISG, fiber optics, and more.

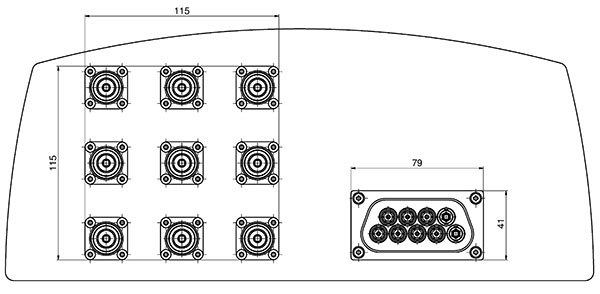

To simplify this growing complexity, SPINNER has developed an innovative solution: the SPINNER Cluster Connector. This modular concept acts as a container that combines multiple technologies, accommodating various connector types and routing them to an antenna or other equipment. The first versions of the Cluster Connector support 2.2-5, 1.5-3.5, and NEX10 RF interfaces, as well as DC, AISG, and fiber optics.

Designed for Maximum Flexibility

Looking ahead, the SPINNER Cluster Connector will be capable of supporting virtually any combination of interfaces, as long as they fit within defined size and mechanical constraints. This flexibility empowers antenna and base station manufacturers, as well as network operators, to determine exactly how many connections—and which technologies—they require. The standout advantage of the Cluster Connector is its ability to unite multiple, diverse technologies in a single assembly.

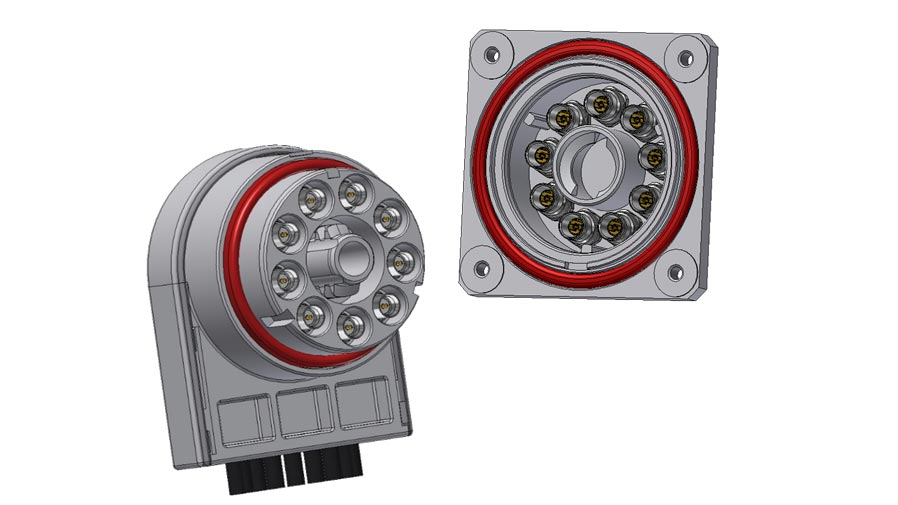

Just like conventional connectors, Cluster Connectors are available in male and female versions. The female cluster is permanently mounted to the equipment by the manufacturer and accepts the male connector cluster during installation.

An Ingenious Approach to Support Miniaturization

The Cluster Connector also supports ongoing trends toward miniaturization. Traditional connectors require ample clearance around them for tools and handling.

The SPINNER Cluster Connector allows connectors to be placed much closer together by preassembling them into a compact unit.

Installation is straightforward: the male cluster slides into the female counterpart and locks in place. For installers, the process becomes simple and efficient—connect, lock, done.

An asymmetrical housing ensures intuitive, error-free installation.

Future-Safe: the Next Connector Generation

A Cluster Connector with nine connections, for example, can be connected extremely quickly. In the traditional approach, an installer must individually mount and secure nine separate jumpers. By contrast, using a cluster reduces the total installation time by up to 90%, as all connections are made in a single step—dramatically lowering labor time and associated costs.

Once the male cluster is plugged in, it locks securely to the housing via a quick-release mechanism, which protects the internal connectors from moisture and dirt. This step is also fast and tool-free, further simplifying installation.

Intelligently Designed Details

To ensure seamless assembly, the male connectors are mounted on floating, rotatable bearings. This allows for slight positional adjustments to compensate for dimensional variations between the male and female clusters. It also enables the jumpers to be realigned easily—for example, when connecting to right-angle interfaces.

Product Finder

Find details about a wide selection of our SPINNER connectors on our Product Finder:

Mobile Communication Catalogs and Brochures Available for PDF Download

Contact with SPINNER

SPINNER GmbH

Erzgiessereistr. 33 | 80335 Munich | Germany | Phone +49 (89) 12601-0