Home » Applications » Rotating Solutions » Industry and Automation

Industry & Automation

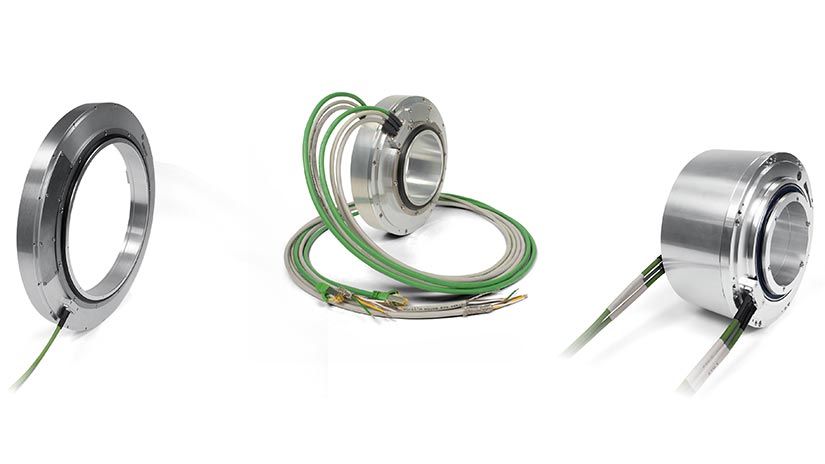

Contactless Data and Power Transmission - Rotary Couplings for Automation Applications

There is a growing need for faster, more accurate data and power transmission via rotary joints for automation applications. SPINNER is now offering a new technology to accomplish this: contactless rotating interfaces based on inductive and electronic coupling.

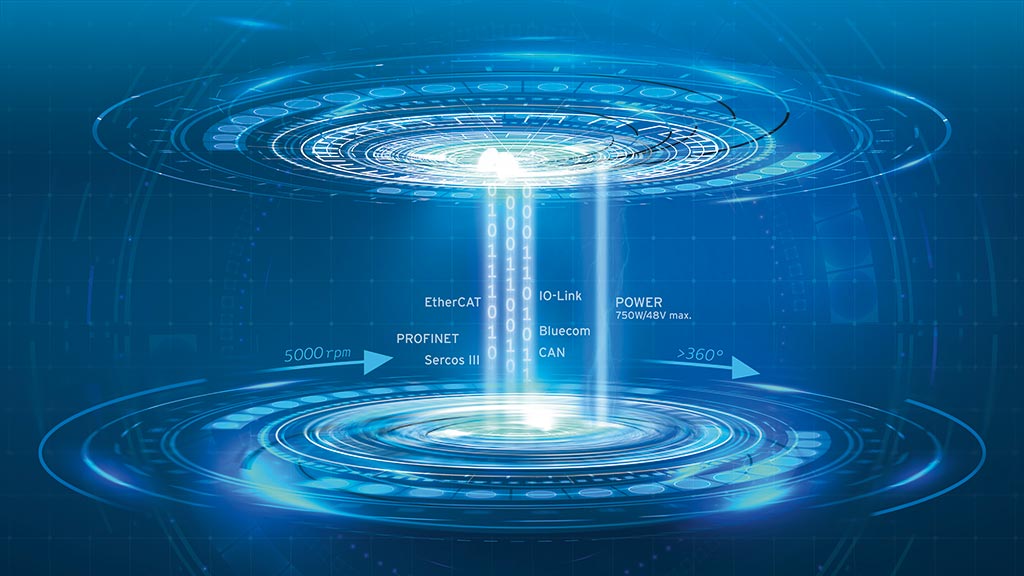

For data transmission, contactless electronic data interfaces are used instead of slip rings. This approach permits transmission rates of up to 1 Gbit/s in Ethernet-based bus systems, also at very fast rotational speeds. 100 Mbit/s real-time feature enables transmission of various, deterministic bus protocols. This paves the way for completely new approaches in automation technology.

Power is transmitted via an inductive system, either by itself or together with data.

Non-Wearing and Maintenance-Free

A further advantage of these contactless data interfaces is that they are non-wearing and maintenance-free.

This avoids the downtimes and costs caused by repairs and servicing. Transmission errors and distortions as a result of micro-interruptions and line reflections are also very effectively prevented, which reduces abnormal data packets and cycle times.

Technical Details of SPINNER Data Transmitters

-

Transmission protocols:

- Bus protocols based on Ethernet protocol IEEE 802.3: Profinet A, B and C, Powerlink, Bluecom, EtherCAT, and Sercos III

- Profibus 12 Mbit/s

- CAN (Repeater-mode)

- RS 422 signals - Automatic adjustment by auto-negotiation in the gigabit Ethernet coupler

- Bit error rates smaller than 1x10-12

- Error-free data transmission at up to 3000 rpm (optionally) in either direction of rotation

- Hollow shaft diameters of up to 360 mm; the insides of hollow shafts remain completely free and available for use by the customer

Technical Details of SPINNER Power Transmitters

- Transmission of industrial 24V DC voltages at up to 300 W (with controlled output voltage and short circuit-proof)

Rotating Solutions Catalogs and Brochures Available for PDF Download

Contact with SPINNER

SPINNER GmbH

Erzgiessereistr. 33 | 80335 Munich | Germany | Phone +49 (89) 12601-0