Home » Applications » Rotating Solutions » Space

Space Applications

Absolutely Reliable Signal Transmission in Space Applications

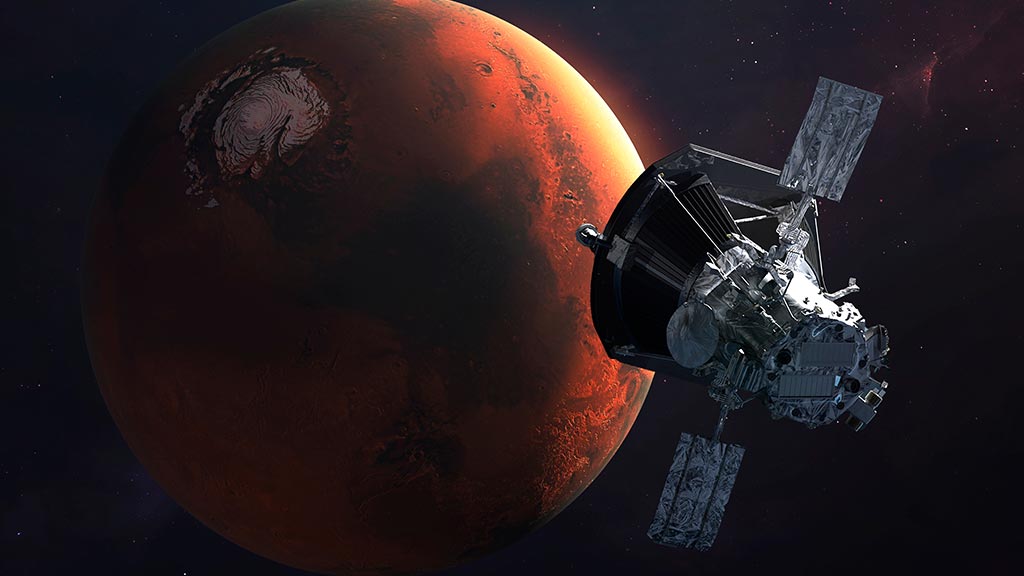

Rotary joints made by SPINNER for use in space make a decisive contribution to technological progress and precise communication because satellites in outer space would be almost worthless if communication links with ground stations were not permanently maintained.

The antennas of satellites have to be permanently targeted at their ground stations, a task for which rotary joints are indispensable. Space, however, presents one of the most extreme environments for our products, demanding the highest levels of reliability, precision, and quality. The severe temperature fluctuations in orbit place immense stress on materials.

Superior Rotary Joints for Space

For rotary joints implemented in space applications, SPINNER designers use special materials that combine low weight and perfect durability. One example are the lubricants used in the bearings, which need to withstand these loads and to be approved for use in space.

Even under the extreme conditions in outer space, a rotary joint has to ensure absolutely reliable signal transmission over the whole service life of the satellite. In addition the lowest possible weight plays a key role.

The wealth of experience that our engineers have with rotary joints in extraterrestrial use and our commitment to continuous product improvement are the basis of our great success. When it comes to application in space, all major customers in Europe already trust in our rotary joints

Test Capabilities

To guarantee the best possible quality of each product, SPINNER offers a wide range of tests.

The requirements and procedures for all testing is specified according to customer needs. Most tests are performed in house, for others SPINNER does cooperate closely with space qualified laboratories close to the SPINNER Westerham site.

Examples for Possible Testing Include:

- Dimensional Check

- RF Measurements

- FEM Analysis

- Thermal Cycling

- Shock & Vibration

- Thermal Vacuum Test

- Additional Test available on request

Additional Services & Capabilities

SPINNER offers a wide range of additional services and capabilities to meet your technical requirements.

Our expertise includes complete RF network integration with waveguides and cables, high-performance Fiber Optic Rotary Joints, and the precision assembly of RF and optical payloads in a Class 7 cleanroom environment.

We also provide PCB launch connectors, advanced measurement equipment, and more—ensuring reliable, high-quality solutions for your projects.

Services & capabilities at a glance:

- Full RF Network including waveguides and/or cables

- Fiber Optical Rotary Joints

- Assembly of RF payloads (Class 7 cleanroom)

- Assembly of optical payloads (Class 7 cleanroom)

- PCB launch connectors

- Measurement Equipment

- And many more

Precision Assembly in an ISO Class 7 Cleanroom

SPINNER also offers high-standard assembly work for space applications, performed in an ISO Class 7 cleanroom spanning approximately 100 square meters. The SPINNER assembly team has extensive experience in RF, mechanical, and optical assemblies.

Rotating Solutions Catalogs and Brochures Available for PDF Download

Contact with SPINNER

SPINNER GmbH

Erzgiessereistr. 33 | 80335 Munich | Germany | Phone +49 (89) 12601-0