Home » Products » Rotating Solutions » Contactless Rotary Couplings

Contactless Data and Power Transmission

Industry 4.0 and the associated networking of machines and equipment are resulting in enormous data volumes. A rapidly lengthening list of processes, spanning everything from production across storage to logistics and shipping, is being automated.

Real-time control is a vital requirement for reliable transmission of data and power. And rapidly rotating components of plants and machines pose especially great challenges.

The electronic rotary transmitters allow data to be transmitted in real time at 100 MBit/s – even at high speeds of up to 5000 revolutions per minute.

Wear- and Maintenance-Free Operation

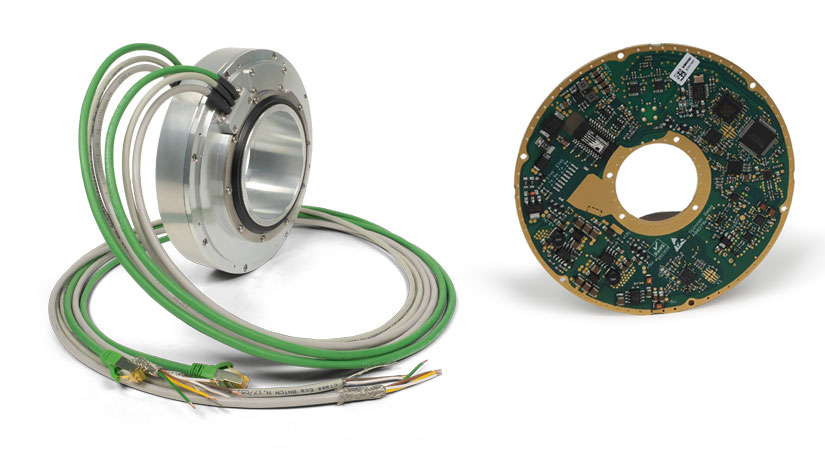

SPINNER offers customers state-of-the-art solutions for maintenance-free, contactless rotary data and power transmission via rotary optical and electronic couplings. Unlike slip rings, rotary couplings from SPINNER are failsafe and have a very long service life. They run in either direction as required, are robust and practically invulnerable to problems and malfunctions, and suffer no wear.

SPINNER doesn’t use sliding contacts for transmitting data from the stator to the rotor. Cat. 6 Ethernet cables and RJ 45 connectors are used for the data connections. Modules can be daisy-chained without any problems, and cables up to 100 meters long can be connected to the input and output. The hollow shafts used have a clear diameter of between 20 and a maximum of 300 millimeters, ensuring plenty of room for implementing virtually any application.

Supported Ethernet Protocols

The rotary couplings support IEEE802.3-based bus protocols. The bit error rate (BER) is less than 1×10-12, even at 99% bus capacity utilization. For applications calling for even higher data rates, 1 Gbit/s transmission models with automatic bus speed detection (autonegotiation) are used.

The following bus protocols are supported: EtherCat (Beckhoff) |Profinet Class A,B, and C (real-time IRT) (Siemens and Phoenix Contact) | Powerlink (B&R) | Bluecom (Bachmann) | Sercos III (Bosch) |VARAN | DriveCliq (Siemens) | CC-Link | IEEE-1588 v2 (PTP) | EtherNET/IP

The SPINNER rotating couplers are also available on request for other bus protocols such as

Profibus | CAN | CANOpen |RS422

Combined data and power transmitters up to 750 W

Contactless data delivers clear benefits in rotating systems whenever slip rings can’t meet requirements due to large diameters, high data volumes and/or infrequent maintenance. This is also true of contactless power transfer systems with hollow cores: they’re preferable whenever failsafe, uninterrupted (24/7) operation is essential at high rotational speeds.

The new compact transmission systems from SPINNER ingeniously combine contactless data transfer, which has proved itself in real-time bus systems, with the ability to supply up to 750 watts. As an added benefit, there is room in the hollow cores for device-specific connections to the rotating unit.

Power transmission specifications

- Input/output voltages: 24 V or 48 V

- Max. transmittable power: 24 V/300 W, 48 V/750 W

- Regulated output voltage with low ripple

- Free inside diameter of 300W version: 20 mm; 750 W version: 50 mm

- Maximum rotational speed: 300 rpm (special versions up to 3,000 rpm)

- Operation independent of speed and direction of rotation

- High efficiency

Uses for application for power and data transmitters

Contactless power and Ethernet modules are ideal for industrial applications, such as bottling plants, fairground rides, machines for producing hygienic products, and cable drums for port cranes. Versions with optical rotary couplings perform outstandingly well in wire rope production machines, construction machinery, packaging systems, industrial robots and very often in radar systems with rotating antennas.

SPINNER Product Portfolio for Rotating Solutions

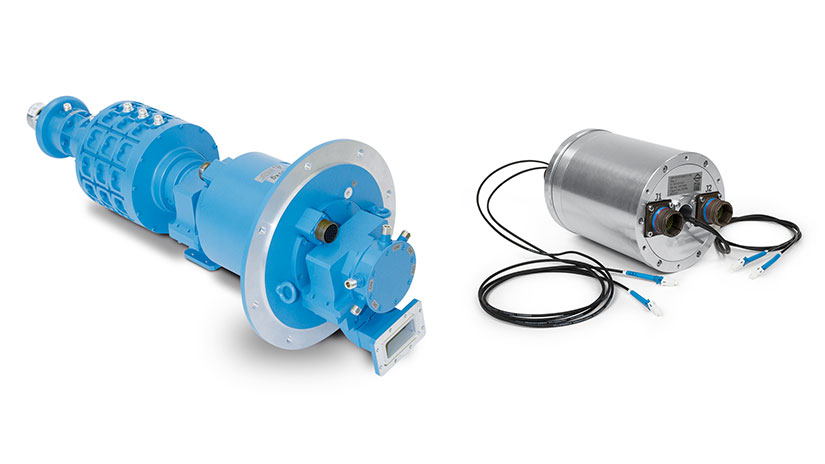

Hybrid Rotary Joints

Any combination is possible: integration of optical rotary couplings, slip rings for high-power or data transmission, media feedthroughs for air or other coolants, encoders, and digital contactless transmitters for Fast Ethernet and high-frequency signals.

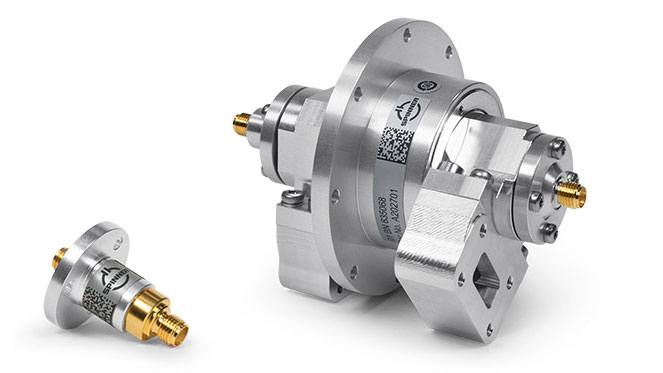

RF Rotary Joints

Our RF rotary couplings provide low insertion loss, consistent transmission characteristics during rotation, and excellent crosstalk attenuation between channels across the full operating frequency range.

Fiber Optic Rotary Joints

Our optical rotary joints deliver signals with low insertion loss and high return loss at high speeds. We offer fiber optic rotary joints with up to 109 channels, as well as custom-designed optical rotary joints.

Contactless Rotary Couplings

Rotating, maintenance-free, contactless data and power transmission through optical and electronic rotary joints. Unlike slip rings, SPINNER rotary couplings are fail-safe and provide a long service life.

Product Finder

Details about a wide range of our products for rotating solutions can be found on our Product Finder:

Rotating Solutions Catalogs and Brochures Available for PDF Download

Contact with SPINNER

SPINNER GmbH

Erzgiessereistr. 33 | 80335 Munich | Germany | Phone +49 (89) 12601-0