Home » News

News - Updates from the World of SPINNER

Here, you can find the latest news about SPINNER GmbH products, offerings, and the newest technological developments.

SPINNER Launches 0.5 mm Test Accessories for Ultra-High-Frequency Measurements up to 250 GHz

The portfolio includes high-end adapters, cable connectors, PCB connectors, and more.

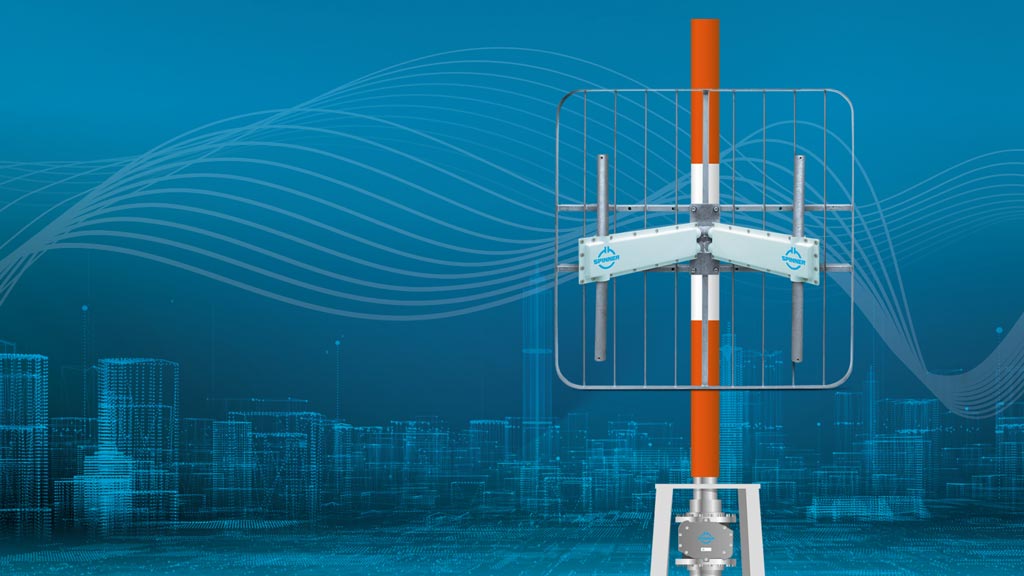

Broadcast Antennas for UHF, VHF and FM

This strategic addition expands our product range with broadcast antennas, trusted worldwide for their performance, reliability, and innovation.

SPINNER GmbH Announces Market Update on Acquired RFS Broadcast Antenna Assets

The acquired intellectual property enables high-performance broadcasting across FM, VHF, and UHF frequency ranges. It includes the full range of the former well-known antenna and combiner portfolio.

Radiating Cables Complement SPINNER PMR/TETRA Portfolio

These cables are mainly used by the fire brigade, police and emergency services. In these areas, it is particularly important to use high-quality components, as problems such as passive intermodulation can cause interference in voice and data communication.

1.0 mm Coaxial Connector: Reliable Connectivity & Measurements Up to 120 GHz!

These products are essential for any RF lab, widely used in vector network analyses (VNA) and millimeter-wave measurements. Also known as Type W connectors, the 1.0 mm coaxial connectors are indispensable for engineers conducting measurements up to 120 GHz.

Cooperation between MoBase by Siemens Mobility and SPINNER

SPINNER GmbH develops and produces premium high-frequency components for signal distribution and transmission to ensure reliable and powerful communication and data transfer, coupled with long lifespan and reduced maintenance efforts.

New 18:6 Multiband Combining System from SPINNER

SPINNER Group Acquires RFS Broadcast IP

This will allow previous customers of RFS Broadcast an opportunity to be supported going forward.

Sustainable Mobile Reception Inside Buildings

SPINNER Newsletter

Receive regular, free updates on SPINNER GmbH, new products and offerings, as well as the latest technological developments.

You can unsubscribe from the newsletter at any time.

Contact with SPINNER

SPINNER GmbH

Erzgiessereistr. 33 | 80335 Munich | Germany | Phone +49 (89) 12601-0